Discover Budget Friendly Bobcat Aftermarket Parts to Match Your Equipment Demands

Wiki Article

Examining the Benefits of Aftermarket Parts in the Maintenance of Equipment and Heavy Devices

In the realm of machinery and heavy tools maintenance, the discussion bordering the use of aftermarket parts is one that triggers inquisitiveness and triggers a closer examination. As specialists entrusted with making sure optimal performance and durability of equipment, it becomes necessary to explore the benefits that aftermarket parts supply. From cost-effectiveness to personalization choices customized to particular needs, these parts provide an engaging situation for factor to consider in the upkeep landscape. Let's dive deeper into the world of aftermarket parts and uncover the benefits that make them a viable option for sectors reliant on efficient equipment operation.Cost-Effectiveness of Aftermarket Components

Making use of aftermarket components for equipment upkeep has been revealed to significantly boost cost-effectiveness without endangering top quality or efficiency. These parts, which are produced by third-party suppliers as alternatives to initial equipment maker (OEM) components, supply numerous advantages in regards to affordability and availability. Aftermarket parts are generally valued less than their OEM counterparts, making them a much more affordable choice for organizations wanting to reduce maintenance expenses without sacrificing integrity.One key aspect adding to the cost-effectiveness of aftermarket components is the open market they exist in. With several suppliers generating these parts, prices comes to be extra affordable, inevitably profiting the customer. The schedule of aftermarket components is usually greater contrasted to OEM parts, as they can be sourced from a variety of distributors and vendors. This accessibility not just minimizes preparations for repairs yet likewise gives versatility in picking the best-priced choice without jeopardizing on high quality.

Wide Schedule and Accessibility

Aftermarket components, understood for their cost-effectiveness in machinery upkeep, demonstrate significant advantages via their large schedule and access out there. Unlike OEM (Original Tools Producer) components that might be restricted to specific dealerships or suppliers, aftermarket parts are commonly created by numerous third-party makers (Bobcat Aftermarket Parts). This prevalent manufacturing leads to a wide circulation network, making aftermarket components easily obtainable to customers across various locationsSimilar High Quality to OEM Components

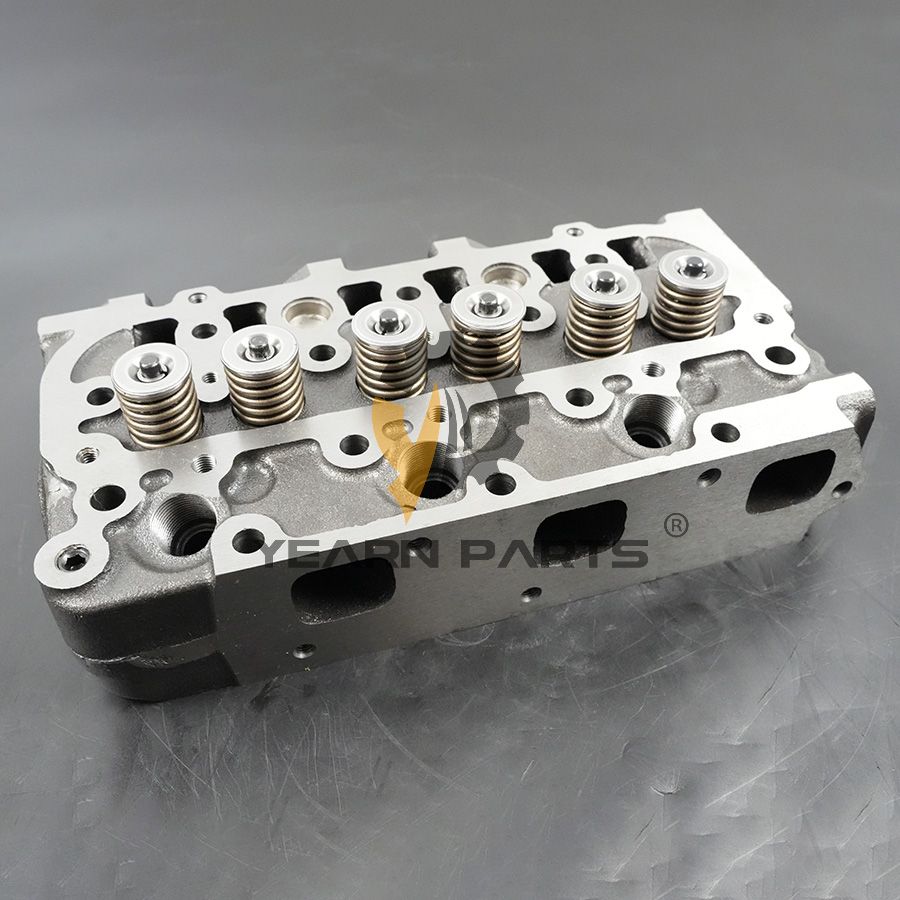

With innovations in producing processes and high quality control criteria, aftermarket parts currently supply a degree of quality that approaches OEM parts. In the past, there was a typical misconception that aftermarket components were of inferior high quality contrasted to initial equipment maker (OEM) parts. Due to technological development and increased competitors in the aftermarket sector, numerous aftermarket makers have considerably boosted their manufacturing processes and materials to fulfill or even surpass the top quality standards established by OEMs.Among the main reasons aftermarket parts currently match OEM parts in high quality is the strenuous testing and qualification procedures that many aftermarket producers abide by. These business comprehend the relevance of generating premium components that can perform dependably in different machinery and devices. Consequently, consumers can now confidently pick aftermarket parts understanding that they use similar high quality to OEM components at a much more economical cost factor.

Personalization Options for Particular Requirements

For equipment upkeep, aftermarket parts supply a range of modification choices customized to particular needs, permitting companies to maximize their devices efficiency efficiently. Modification is this article a crucial advantage of aftermarket components as it enables firms to adapt components to satisfy unique needs that may not be read more resolved by conventional OEM parts.Additionally, aftermarket components distributors can work closely with services to understand their specific obstacles and design components that attend to these issues effectively. Bobcat Aftermarket Parts. This personalized technique to customization can cause enhanced devices capability, enhanced productivity, and lowered downtime as a result of tailored remedies that line up with the company's operational goals. By leveraging aftermarket get rid of modification options, companies can enhance their equipment to carry out at its ideal, ultimately causing enhanced overall operational efficiency and cost-effectiveness

Swift Delivery and Decreased Downtime

Provided the customized services given by aftermarket parts for specific machinery demands, businesses can profit from swift distribution and minimized downtime through efficient supply chain administration approaches. By partnering with trustworthy aftermarket components companies, services can access a large range of products quickly, making sure that upkeep and repairs are brought out promptly to obtain equipment back up and running.Decreased downtime is crucial for maintaining productivity levels and meeting project target dates. By having accessibility to a varied stock of aftermarket components that can be delivered immediately, organizations can stay clear of extensive durations of equipment lack of exercise. This performance in supply chain monitoring not just conserves time yet additionally adds to set you back financial savings by lowering the effect of downtime on general operations. In final thought, the speedy delivery of aftermarket parts plays an important function in reducing downtime, improving functional efficiency, and inevitably ensuring the seamless functioning of equipment and hefty devices.

Final Thought

Unlike OEM (Initial Tools Supplier) components that may be restricted to particular dealers or producers, aftermarket parts are commonly produced by numerous third-party suppliers (Bobcat Aftermarket Parts). Furthermore, the competitive market for aftermarket components commonly results in reduced costs and promotions, allowing clients to obtain top quality parts at a minimized price compared to OEM parts

With improvements in manufacturing procedures and quality control standards, aftermarket components now use a level of top quality that is similar to OEM parts. In the past, there was an usual misconception that aftermarket parts were of inferior quality contrasted to original tools maker (OEM) parts.One of the main factors aftermarket parts currently rival OEM parts in high quality is the rigorous screening and accreditation procedures that lots of aftermarket producers adhere to.

Report this wiki page